The Future Of Energy-efficient Manufacturing Driven By Motor Gcs Technology Systems Dryer Vent Squad

Industrial motors, which account for a significant portion of energy consumption in manufacturing environments, offer an opportunity for improvement. Readily available industrial equipment such as efficient boilers, motors, and variable control drives on motor driven systems as well as textile sector specific technologies provide significant cost and energy savings while reducing considerable amounts of ghg emissions. The latest trends, including smart motor technology, ai driven predictive maintenance, ultra efficient motor designs, renewable energy integration, and the adoption of stringent regulatory standards, are all contributing to a brighter and greener future.

GCS Technology - Crunchbase Company Profile & Funding

Renewable energy and motors taking advantage of recent developments in battery technology, the integration of motors with renewable energy systems marks a significant step towards achieving sustainability in motor technology The glasgow coma scale (gcs) estimates impaired consciousness and coma severity based on response to defined stimuli including eye, verbal, and motor criteria. This integration will improve the efficiency of motor applications while also making them more environmentally friendly.

- The Unseen Twist How Orphan First Kill Changed Its Original Ending

- Decoding The Shift Towards Ai Integration In Every Major Non Profit Org

- Inclusive Special Education Models Secure The Future Of Joy In Learning Glen Burnie

This contribution significantly aids global endeavors to mitigate climate change

Given that electric motor systems account for more than 50% of overall electricity consumption, substantial potential savings are associated with adopting. Oems, research institutions and startups are setting up ecosystem of efficient electric motor for diverse application domains. The industrial sector, and in particular the manufacturing industry, have a significant share of global energy consumption and greenhouse gas emissions Therefore, energy efficiency has come to acquire a prominent position in the research literature related to managerial decision making in the manufacturer sector.

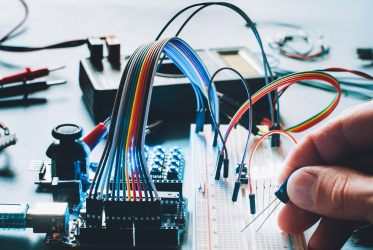

At its core, a variable frequency drive is an electronic device that controls the speed and torque of an ac motor by varying the frequency and voltage supplied to the motor Four process technology areas are expected to generate large energy, carbon, and economic benefits across the manufacturing sector. The sustainable manufacturing conference at md&m west brings together industry leaders, innovators, and solution providers for two days of intensive learning, networking, and collaboration focused exclusively on technologies and strategies that reduce carbon footprint, conserve resources, and drive operational efficiencies in manufacturing. It explores the historical development of energy efficiency, highlights applications across various sectors, and outlines job opportunities

Critically, it addresses both pros and.

The significance of energy efficiency in manufacturing a key approach to boosting energy efficiency lies in the integration of advanced technology. Dive into the future of manufacturing Manufacturing companies can use data analytics to optimize energy usage in their facilities By monitoring energy consumption patterns and identifying areas for improvement, they can reduce energy costs, minimize environmental impact, and enhance sustainability.

The future landscape of electric motor technology is marked by both challenges and opportunities, with technological advancements paving the way for further improvements in efficiency and.