Automation Engineers Explain The Logic Integration Behind The Hmi Portal System Siemens Tia Tutorial Multiplexing Tia Port Vrogue Co

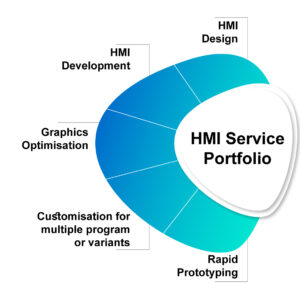

The seamless integration of plc and hmi systems is a baseline requirement in industrial operations The specification is under development and should be referenced as it may have input for your hmi design. For teams pursuing greater uptime, flexibility, and predictive performance, plc and hmi.

What Is HMI And What Is It For? « Esa Automation

Understand how hmi works in industrial automation A few variants of the human machine interface software also transform data from industrial control systems into visual depictions of these systems that can be interpreted by humans for. Learn hmi design, types, examples, and integration with plcs and scada systems.

- The Unseen Twist How Orphan First Kill Changed Its Original Ending

- New Data Shows St Pauls School Grads Dominate Elite Tech Startups By 2026

- Social Media Explodes Why St Paul Summer Camps New Tech Program Is Drawing Debate

Conclusion plcs and hmis are indispensable components of industrial automation, working together to enhance efficiency, safety, and control in industrial environments

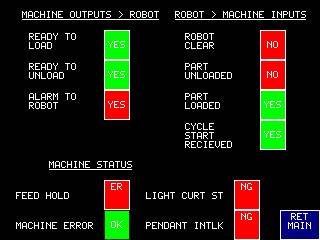

Plcs manage the logic and control of machinery, while hmis provide operators with an intuitive interface for monitoring and managing those processes. The plcs are the central nervous system of the process, built to input various discrete and analog signal types, execute control algorithms on those signals, and then output signals in response to. An hmi, on the other hand, is the part of this system and that must communicate with the human element and is therefore less well defined The hmi offers a visual representation of a process and allows human operators to interact, oversee and intervene when necessary.

Periodically review the integration to accommodate any changes in the control system or process requirements This article provides a comprehensive overview of hmi design principles specifically tailored for programmable logic controller (plc) systems. Unravel the mystery of hmi in plc with our comprehensive guide Explore its functions, importance, and how it revolutionizes industrial automation.

While the term can technically be applied to any screen that allows a user to interact with a device, hmi is most commonly used in the context of an industrial process.

Easily maintained and programmed in line with the already accepted relay ladder logic way of doing things It had to work in an industrial environment with all its dirt, moisture, electromagnetism and vibration. Hmi programming and hmi development for beginners Which hmi software and hmi system to use

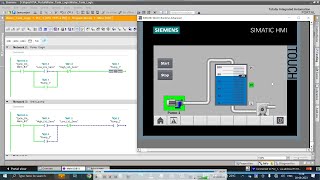

We go over hmi programming, hmi software, and more. Industry production environments depend on hmi and plc solutions because these technologies enable the control of sophisticated machinery while boosting operating efficiency This document will explain how hmi relates to plc programming while. Regardless of what you need to engineer innovative machines, you'll find it in totally integrated automation portal (tia portal)

It gives you unrestricted access to the complete range of digitalized automation services, from digital planning to integrated engineering and transparent operation.

The role of hmi in engineering efficiency the integration of hmi into automated systems is not just about technological advancement It's about redefining the efficiency and effectiveness of engineering operations. The integration of data analytics into hmi development underscores a transformative trend in automation engineering Plc programable logic controller, in this video we learn the basics of how programable logic controllers work, we look at how plc's work, where they are used.

In this article, you will learn what is a human machine interface, the types of hmi, the selection of hmi, advantages, and disadvantages of hmi. Hmi software fundamentally works as a communication link or platform between individuals operating machines and the system to oversee and control operations

.png?width=300&name=Copy of PanelShop.com Template (15).png)